In the packaging industry, PET bottles (Polyethylene Terephthalate) are becoming the top choice thanks to their durability, transparency, and high recyclability. From beverages, shampoos, and shower gels to hand sanitizers and cleaning solutions, PET bottles are widely used across the market.

Today’s consumers also prefer eco-friendly products. As a result, many brands have shifted to using PET packaging to not only meet aesthetic demands but also reduce non-biodegradable plastic waste. This trend has further increased the importance of PET bottle manufacturers in providing high-quality and sustainable packaging solutions.

What is a PET bottle?

A PET bottle is made from PET (Polyethylene Terephthalate), a type of thermoplastic belonging to the polyester family, and is now widely used in the packaging industry. PET bottles are highly transparent, lightweight yet durable, resistant to impact, and difficult to crack or break. This material is also safe for direct contact with food, cosmetics, and pharmaceuticals. In addition, it is highly flexible, allowing easy molding into various designs, capacities, and colors.

Notably, PET bottles are recyclable, helping to reduce plastic waste and making them more environmentally friendly. Thanks to these outstanding characteristics, PET bottles are commonly used for beverages, carbonated drinks, shampoos, shower gels, hand sanitizers, cosmetics, and many other consumer products.

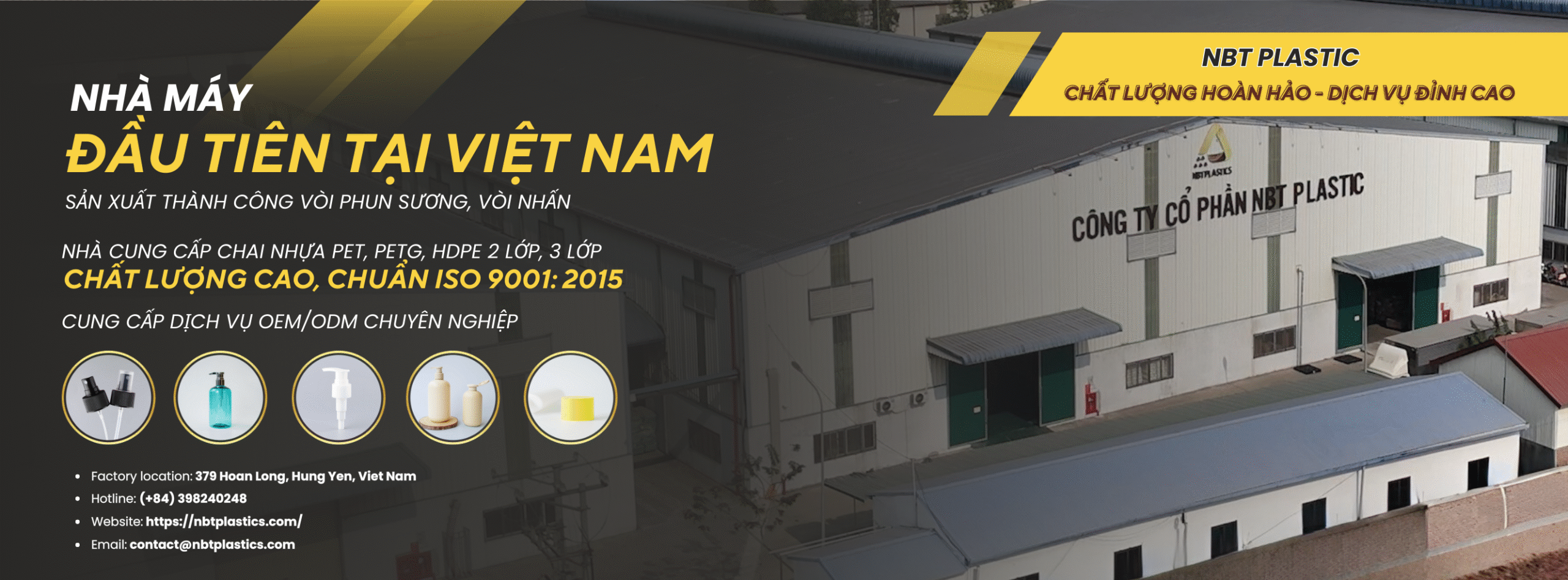

NBT Plastic – a trusted PET bottle manufacturer in Vietnam

NBT Plastic is recognized as one of the leading PET bottle manufacturers in Vietnam, specializing in providing packaging solutions for cosmetics, pharmaceuticals, and consumer goods. With many years of experience, NBT Plastic not only focuses on large-scale production but also ensures consistent quality across every product.

The company’s strength lies in its modern machinery, automated production lines, and strict quality control processes. As a result, every PET bottle manufactured meets high standards in clarity, thickness, and durability, fully satisfying the requirements of both domestic and international clients.

Outstanding advantages of PET bottles from NBT Plastic

When choosing PET bottles from NBT Plastic, customers can be assured of:

-

Exceptional durability: PET material has strong resistance, making bottles difficult to crack or break during transportation or use.

-

High aesthetics: the clear and glossy surface highlights the value of the product inside.

-

Safety: PET is tested and proven safe for direct contact with food and cosmetics.

-

Flexibility: easy to mold with a wide variety of designs, sizes, and capacities to meet different needs.

-

Recyclability: supports green production trends, reducing negative impacts on the environment.

Modern production process at NBT Plastic

As a professional PET bottle manufacturer, NBT Plastic applies a closed-loop production process that includes the following steps:

-

Selecting high-quality virgin or recycled PET materials.

-

Using precision technology to produce PET preforms with accurate dimensions and weight.

-

Automatically blow-molding bottles on advanced production lines to ensure the correct shape and design.

-

Conducting quality control at every stage to eliminate defective, cracked, or deformed products.

-

Carefully packaging and delivering safely to customers.

Thanks to this modern process, NBT Plastic ensures consistent product quality while being able to fulfill large orders within a short lead time.

Diverse designs and customized solutions

NBT Plastic not only manufactures PET bottles based on available models but also offers custom design services and new mold development upon request. This allows brands to create exclusive packaging that carries their unique identity in the market.

Tiếng Việt

Tiếng Việt