What Is PCR Plastic? How It Differs From Post-Industrial Recycled (PIR) Plastic

To better understand PCR plastic, it is important to distinguish it from Post-Industrial Recycled (PIR) plastic:

-

PCR Plastic (Post-Consumer Recycled): This type of plastic is collected from used plastic products discarded by end consumers (e.g., water bottles, milk cartons, shampoo bottles, etc.). The material is cleaned, sorted, shredded, melted down, and recycled into new plastic pellets for packaging production.

-

PIR Plastic (Post-Industrial Recycled): This type of plastic is recycled from scraps, surplus materials, or defective products generated during the industrial manufacturing process, before reaching consumers. PIR plastic is generally cleaner and easier to recycle, but it does not address the issue of post-consumer plastic waste.

💡 Key Difference: PCR plastic directly tackles the massive amount of post-consumer plastic waste, helping to reduce the burden on landfills and oceans.

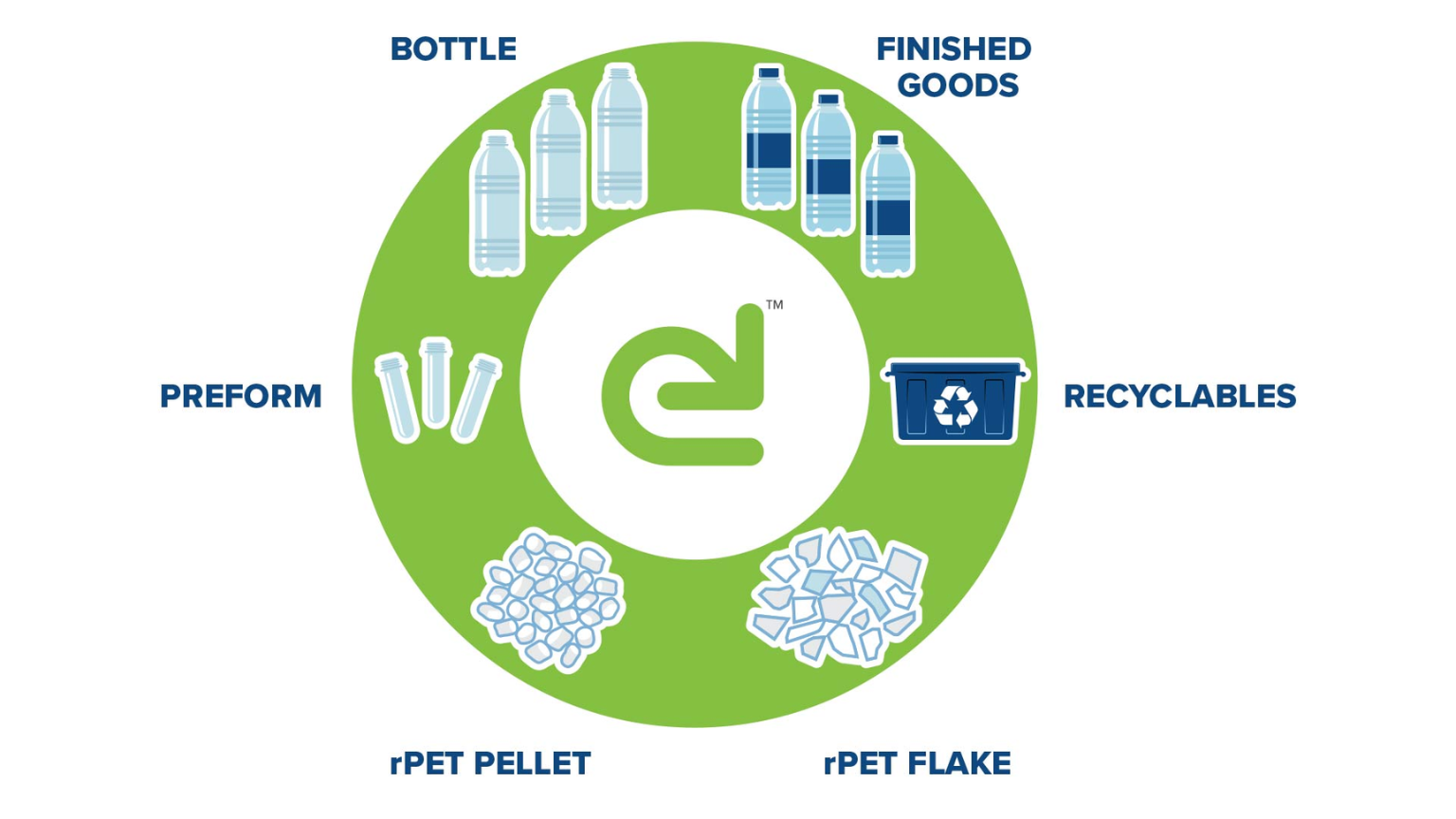

PCR Plastic Production Process

-

Collection: From households, residential areas, and collection points.

-

Sorting: By polymer type (PET, HDPE, PP, etc.) and color.

-

Cleaning: Multiple washing stages to remove labels, impurities, and chemical residues.

-

Shredding: Turned into plastic flakes.

-

Recycling: Melted and processed into plastic pellets—ready for new packaging production.

Common Types of PCR Plastic and Their Packaging Applications

Currently, the two most widely used types of PCR plastic are rPET and rHDPE:

Nội dung chính

rPET (Recycled PET)

-

-

-

Properties: Transparent, lightweight, durable, and resistant to moisture. Color may appear slightly grayish due to recycling.

-

Applications: Used in producing water bottles and cosmetic packaging (shampoo, shower gel, makeup remover bottles). With proper processing, rPET can be made into food-grade rPET, safe for direct food contact.

-

-

Businesses Need to Note

PCR plastic packaging for food and pharmaceuticals must comply with strict standards set by regulatory agencies such as the FDA or EFSA.

Benefits of Using PCR Plastic Packaging

Switching to PCR plastic packaging brings multiple advantages:

-

Reduce plastic waste: Directly cuts down the amount of plastic ending up in landfills and oceans.

-

Save resources: Limits the extraction of petroleum and natural gas for virgin plastic production.

-

Lower carbon emissions: Producing PCR plastic consumes less energy, significantly reducing greenhouse gas emissions.

-

Meet market demand:

-

Consumers increasingly prefer products with sustainable packaging.

-

Many countries enforce EPR (Extended Producer Responsibility), requiring businesses to recycle and reduce single-use plastics.

-

-

Build a green brand: Demonstrates environmental responsibility, strengthens credibility, and attracts customers and partners.

PCR Packaging Solutions at NBT Plastic

NBT Plastic is proud to be one of the pioneers in providing high-quality PCR plastic packaging solutions in Vietnam.

-

Diverse portfolio: Bottles and containers made from rPET and rHDPE in various capacities and designs, suitable for cosmetics and personal care products.

-

Quality & safety: All NBT Plastic products undergo strict quality control processes and come with full certifications for material origin and safety.

-

Expert consultation: A dedicated team supports businesses in choosing the optimal PCR packaging solution in terms of cost, design, and sustainability standards.

With state-of-the-art production lines and products that meet international standards, NBT Plastic goes beyond simply supplying cosmetic plastic packaging — we deliver comprehensive solutions (ONE STOP SERVICE). This is the key advantage that helps businesses strengthen their position in the global market.

Tại NBT Plastic, quy trình sản xuất được triển khai khép kín, từ khâu thiết kế, sản xuất vòi nhấn, chế tạo chai nhựa PET & HDPE cho đến in ấn trực tiếp trên bao bì. Nhờ sở hữu nhà máy quy mô lớn với công suất đạt tới 50 triệu sản phẩm mỗi tháng, công ty hoàn toàn có khả năng đáp ứng những đơn hàng số lượng lớn từ các thương hiệu toàn cầu.

In addition, focusing production within a unified ecosystem helps optimize transportation costs, while ensuring strict quality control and customer information security. These are the core values that set NBT Plastic apart in the market.

Thanks to these outstanding advantages, NBT Plastic has become a trusted partner of many international cosmetic brands, while also pioneering in the development of green and sustainable packaging, thereby contributing to strengthening the position of Vietnam’s plastic packaging industry on the global map.

Tiếng Việt

Tiếng Việt